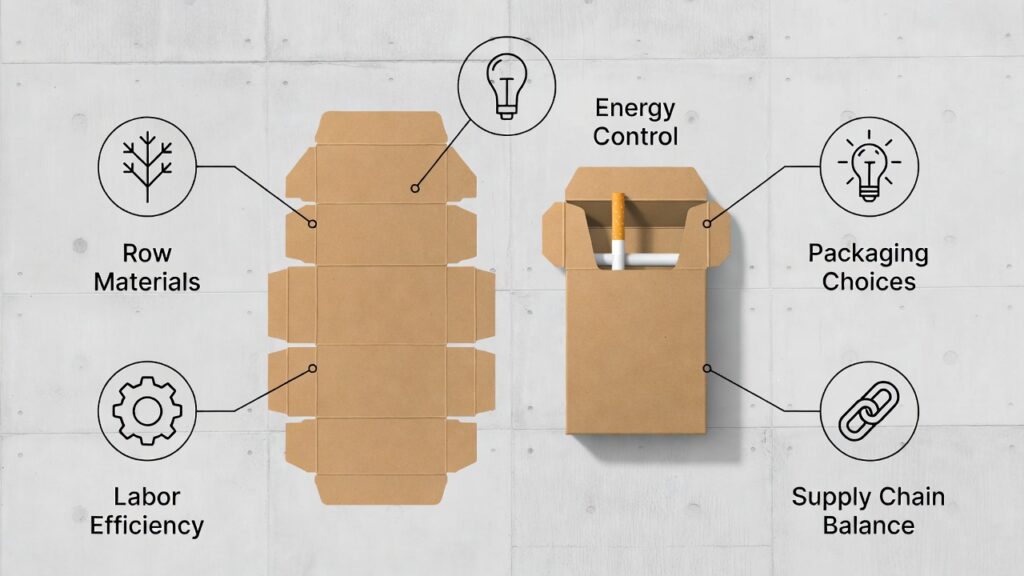

How Smart Cigarette Business Owners Optimize Production Costs Without Cutting Corners

Ask any experienced cigarette business owner what keeps them up at night, and the answer is rarely competition alone. It’s rising costs. Raw materials cost more. Energy bills keep piling up. Labor gets harder to manage. And yet, the product price cannot always move the same way. This is why successful players in the cigarette business don’t rely on luck or shortcuts. They rely on quiet optimization. Small and smart decisions across production that add up over time.

Cost reduction is not entirely about cutting corners. But it also focuses on tighter and more thoughtful operations. Let’s walk through how seasoned tobacco manufacturers actually do it.

Raw Material Savings: Control the Leak Before It Becomes a Flood

Raw materials are where money disappears first and fastest in cigarette production. They account for a significant portion of cigarette production costs. Tobacco leaves, paper, filters, and additives all add up quickly, especially for manufacturers operating at scale. Most cigarette business owners learn early on that buying small quantities is expensive. Bulk purchasing is not just about getting discounts. It’s about stability. When you pick big orders from suppliers, it automatically lays the concrete grounds to build a long-term relationship. You gain influence and a competitive edge, also. You have consistency to maintain the same level of quality while controlling the price and deliveries.

But smart sourcing goes beyond bulk buying. Waste is the real enemy here. Poor storage, careless handling, or outdated cutting methods can quietly drain profits. Even small losses per batch add up across thousands of units. That’s why experienced tobacco manufacturers obsess over material handling, storage conditions, and process discipline. Saving raw materials doesn’t mean lowering quality. It means respecting every input that goes into the final product.

Manufacturing Efficiency: Where Real Savings Are Made

In a manufacturing factory, the production floor is that one place where the cost optimization really payback. Many cigarette business owners now prefer gradual machine upgrades instead of waiting for complete failure.

Labor Optimization: Avoiding Fewer Mistakes

Labor is tricky. Too many workers raise costs. Too few increase risk. Smart cigarette business owners don’t think in terms of “cutting staff.” They think in terms of using skills better. Training is one of the most underrated cost reduction strategies. A trained worker will always save you from wasting less material. Skilled workers will handle machinery properly, and spots problems early. Even they are so much experienced that they can repair machines themselves. This reduces rework, downtime, and quality issues. These are all expensive problems.

Clear roles also matter.

Packaging and Materials: Spend Smarter, Not Bigger

Energy and Operations: Small Fixes, Big Impact

Energy costs rarely show up as a crisis. They show up as a slow drain. If highly tech energy-efficient machinery is used, cigarette business owners can cut costs by using less power. While preserving output. If cigarette manufacturers make simple operational changes, they don’t have to invest in major upgrades. So simple changes can make huge differences. Efficient lighting reduces monthly utility bills. Then there are proper shutdown procedures and scheduled maintenance that can save lots of bucks than most managers could expect. Some cigarette manufacturers now track energy usage just as closely as raw material usage. When you measure it, you can control it. Lower energy waste means higher manufacturing efficiency without changing the product itself.

Supply Chain and Inventory: Avoid the Extremes

Inventory mistakes are expensive in both directions. Too much stock ties up cash and storage space. Too little leads to production delays and rushed orders. Holding too few risks results in production delays. The smartest cigarette business owners aim for optimal stock levels, not extremes. Perfection over balance is the key to many successful cigarette business owners.

Go followed this strategy and saved millions. In the supply chain stage, always remember to make an accurate demand forecasting. logistics partners and above all, supplier coordination. If you master these three areas, you will never go out of stock. You don’t have to worry about running low on meeting the demand and supply. No storage cost worries. Thus, running the production smoothly.

Final Thoughts: Cost Control Is a Habit, Not a Hack

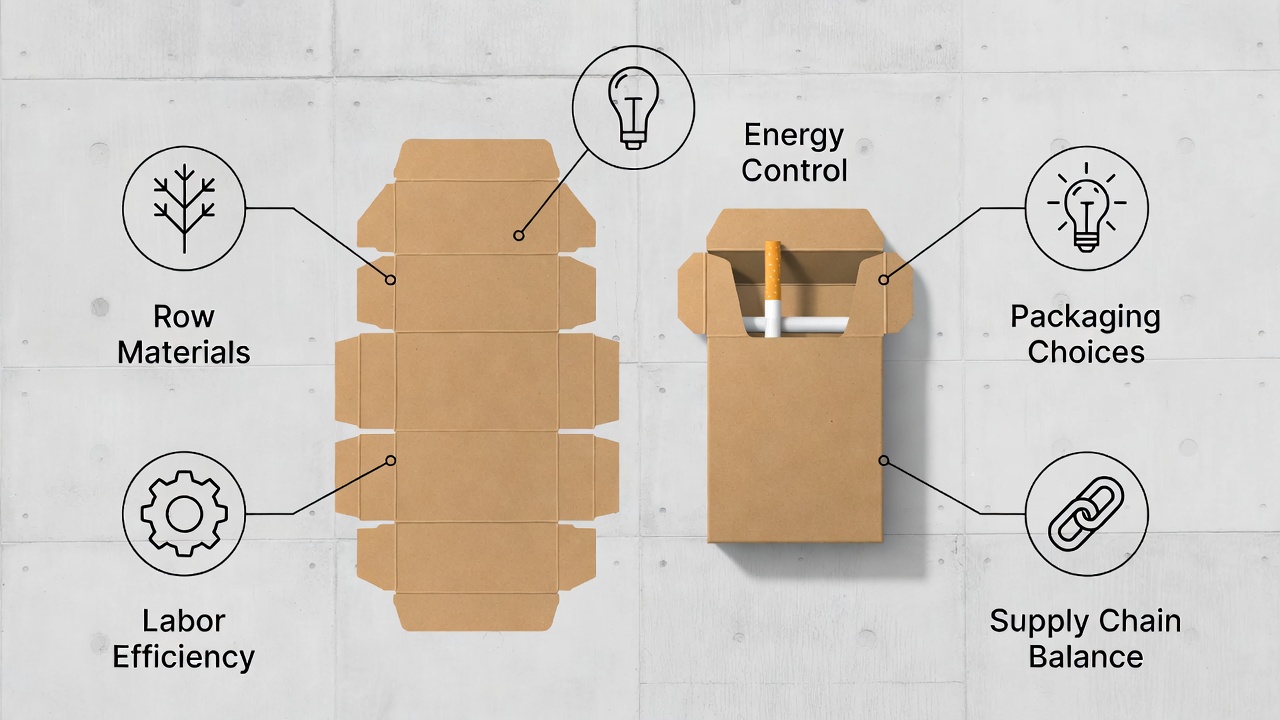

There is no single formula for reducing costs in the cigarette business. The brands that remain profitable are the ones that consistently question their processes: Can this step be cleaner? Can it be faster? Can costs be lowered without sacrificing quality? From raw materials and production workflows to labor efficiency, supply chain balance, and smart packaging decisions like Custom kraft Cigarette Packaging Boxes, cost optimization is an ongoing process. It’s quiet, intentional, and built through steady operational improvements rather than quick fixes.