If you’re talking about CNC precision turned components, one thing gets overlooked a lot: the material. People obsess over machines, feeds, speeds, and tooling, but the raw material? That’s what makes or breaks your part. Pick wrong, and you might as well throw the whole batch in the trash. Pick right, and the part just works, sometimes better than you hoped. So let’s just get into it and talk really about what people actually use, why, and what quirks you’ll run into.

Steel: The Old Reliable

Steel’s everywhere in CNC turning. Carbon steel, stainless, alloy, you name it. Carbon steel is cheap and strong, but yeah, it rusts if you leave it outside. Stainless steel is more forgiving, resists corrosion, and looks cleaner, but you pay for it. Alloy steels are trickier, they’re made for high-stress jobs or extreme temperatures. Tough, durable, but sometimes a pain to machine. You’ve got to balance cost, strength, and machinability.

People think “just use steel” for everything. Not really. It depends on the job. Some parts bend under load, some just need to survive chemical exposure. You can’t just grab whatever’s lying around.

Aluminum: Light and Fast

Aluminum is like the favorite kid in the shop. Easy to machine, light, and resists corrosion naturally. You can anodize it for extra hardness or just for looks. It’s perfect for electronics, aerospace, automotive, anywhere weight matters. But beware—soft aluminum scratches and dents more easily than steel, and it can expand under heat. Doesn’t matter for some parts, but it’s critical for others.

The thing about aluminum is speed. CNC precision turned components come off faster, tools last longer, and production runs are smoother. But don’t get cocky. Too fast, too aggressive, and you’ll have chatter marks everywhere.

Brass and Copper: Niche Players

Brass is easy to machine, doesn’t spark, and works well in fittings, bushings, and decorative stuff. Copper is mostly electrical, soft, conductive, but can be sticky under the cutter. Neither is cheap, but when you need them, you really need them. People underestimate the quirks, though. Even “easy” metals can mess up a job if your feeds are wrong or your tooling dull.

Titanium: Tough but Tricky

Titanium looks sexy on paper, light, strong, corrosion-resistant. Reality check: it’s hard to machine. Heat builds up fast, tools wear quickly, and mistakes are expensive. Aerospace, medical, motorsports, these guys love it. For a normal shop? Probably not unless you’ve got the right gear and patience. But if you nail it, the part is basically indestructible.

Plastics: Don’t Ignore Them

Not every part needs metal. Plastics like Delrin, nylon, or PEEK do a lot of work. They’re lighter, quieter, sometimes cheaper, and handle chemicals pretty well. Delrin is practically a workhorse in machines. PEEK is high-end, expensive, can take heat, chemicals, but it’s worth it if your parts get abused.

Composites are getting more common, too. Carbon fiber reinforced plastics, glass-filled nylon, they’re strong and light, but tricky under a cutter. Mess up the feed rate or fixturing, and the whole piece is ruined.

Alloys: Tweaking for Performance

Base metal only tells part of the story. Alloys exist because no metal is perfect. Steel with chromium or molybdenum? Harder, more wear-resistant. Aluminum alloys? Better strength-to-weight, more corrosion-resistant. Plastics can be reinforced, too. CNC precision turned components made from the right alloy in recent years, where a standard version would fail.

Surface Treatments Matter

Don’t sleep on finishing. Steel might rust in days if untreated. Aluminum looks dull without anodizing. Plastics are usually fine raw materials, but chemical coatings can make them last longer. CNC precision turned components often go through at least one treatment, sometimes just polishing, sometimes plating, hardening, or passivation. It affects durability and how the part functions.

Trade-Offs: Nothing’s Perfect

Here’s the hard truth: no material is perfect. Steel is strong but heavy. Aluminum is light but can deform. Plastics are cheap but wear faster. Titanium is awesome, but expensive and a pain to machine. You always weigh cost, environment, and performance. Plus, machinability matters. Some metals gum up tools, some cut like butter. That stuff changes cycle times and scrap rates.

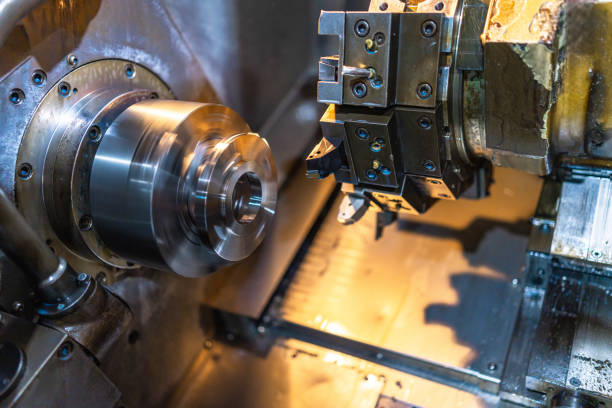

Why It Matters in CNC Turning

CNC precision turned components aren’t forgiving. Material choice affects tolerances, tool wear, finishing, and speed. Pick poorly, and you struggle to hit specs or scrap half your parts. Pick wisely, and the parts practically come off the machine themselves.

Also, some materials demand more from your setup. Exotic metals? You need proper fixturing, cooling, and a careful operator. Plastics? Slow speeds, gentle handling. Aluminum? Fast, sharp tools, steady hands. Material choice drives the process as much as the design.

Swiss CNC Machine Contract Manufacturers Can Help

If you need extremely tight tolerances or complex parts, Swiss CNC machine contract manufacturers are worth looking into. They specialize in tiny, precise, sometimes fiddly components. They know how to deal with titanium, stainless steel, or tough plastics. You get parts that hit spec, repeatably, without the usual headaches. High-volume runs, small intricate parts, they’ve got the experience most shops just don’t.

Common Misconceptions

Steel isn’t always best. Titanium isn’t always overkill. Plastics aren’t always “easy.” Material choice is about function, not cost, hype, or what sounds cool. People mess up here all the time. Think through the job, environment, tolerances, and lifespan before you pick.

Conclusion: Think Smart, Machine Smart

Choosing materials for CNC precision turned components isn’t just ticking a box. Strength, cost, machinability, environment, they all matter. Metals like steel, aluminum, titanium, brass, and copper cover most needs. Plastics and composites work when metals don’t. Alloys and finishes tweak performance. And if your parts need extreme precision or complicated geometry, Swiss CNC machine contract manufacturers can be the difference between frustration and perfect parts.