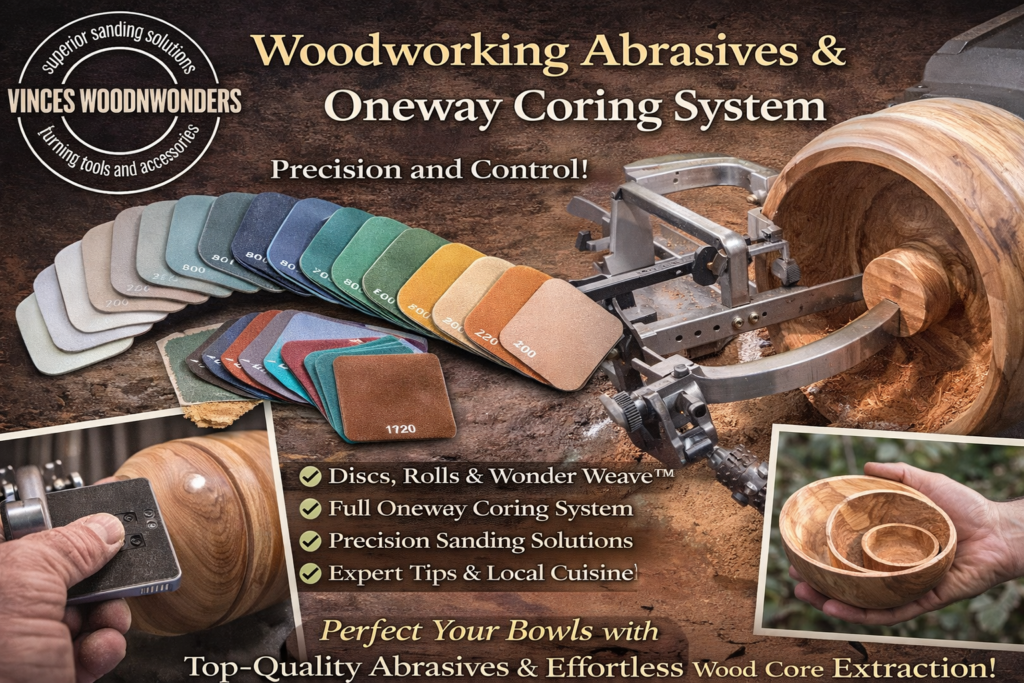

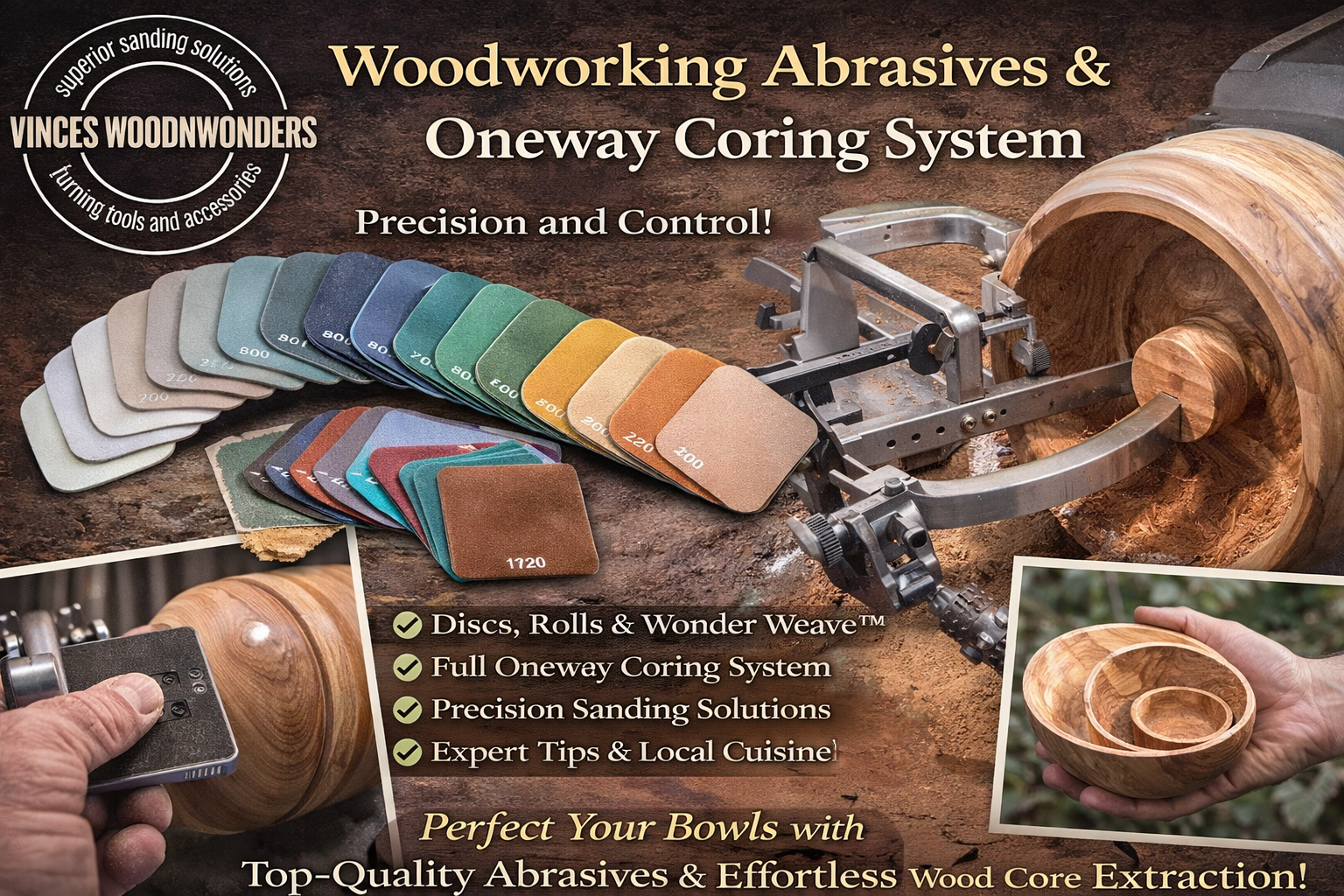

Woodturning today is about more than shaping wood—it is about precision, efficiency, sustainability, and finish quality. Two essential components that define a high-level workshop are woodworking abrasives and the Oneway coring system. When used correctly, these tools allow woodturners to maximize material yield, improve finishing results, and streamline production.

At Vince’s Wood N’ Wonders, the focus is on equipping woodturners with tools that enhance both craftsmanship and profitability. Understanding how woodworking abrasives and the Oneway coring system work together can transform your turning process from start to finish.

Understanding Woodworking Abrasives

Woodworking abrasives are fundamental to achieving a refined, professional finish. No matter how skilled the turning technique, the final appearance of a piece depends heavily on sanding quality.

Abrasives function by gradually removing material through friction. Available in sanding discs, sheets, belts, and foam-backed pads, each type serves a purpose depending on the shape and size of the project.

Grit Selection and Progression

Proper grit progression is critical when using woodworking abrasives:

- 60–100 Grit: Removes tool marks and levels uneven surfaces.

- 120–220 Grit: Refines the surface and eliminates scratches left by coarse grits.

- 320 Grit and Above: Prepares the wood for finishing oils, waxes, or lacquer.

Skipping grit levels is one of the most common mistakes in woodworking. Each abrasive stage removes scratches from the previous grit. If you skip steps, those scratches may remain hidden until finish is applied—at which point they become highly visible.

Modern Innovations in Woodworking Abrasives

The woodworking industry continues to evolve with improved abrasive technologies designed for durability and efficiency.

Advanced Materials

Today’s woodworking abrasives often feature:

- Aluminum oxide grains for consistent cutting

- Ceramic abrasives for longer lifespan

- Mesh sanding discs that reduce clogging

- Hook-and-loop backing systems for quick changes

- Foam interface pads for curved surfaces

These improvements allow woodturners to sand more efficiently while maintaining consistent pressure across complex curves.

Dust Control and Health

Dust management has become a major priority in modern workshops. Pairing woodworking abrasives with proper dust extraction systems helps reduce airborne particles and improves visibility while sanding. Clean air not only protects health but also improves finish quality by preventing dust contamination during finishing.

Introducing the Oneway Coring System

While woodworking abrasives refine surfaces, efficiency begins during the shaping process. The Oneway coring system is designed to extract multiple bowls from a single blank, dramatically increasing material yield.

Traditional bowl turning removes large volumes of interior wood as waste. In contrast, the Oneway coring system allows woodturners to separate nested bowl forms from within a single blank, reducing waste and maximizing value.

This method is especially valuable when working with expensive hardwoods, burl blanks, or rare species where every inch of material matters.

How the Oneway Coring System Works

The Oneway coring system operates with a curved cutting knife mounted on a guided support arm. As the blank rotates on the lathe, the cutting knife follows a controlled arc into the wood, separating a smaller bowl from inside the larger one.

Key features include:

- A stable base platform

- Curved coring knives

- Support fingers to minimize vibration

- Sharpenable and replaceable cutters

This design ensures smooth, controlled cuts and reduces stress on both the lathe and the woodturner.

By coring instead of hollowing out entirely, you save time and reduce physical strain while producing additional usable forms.

Benefits of the Oneway Coring System

Increased Profitability

When you can produce two, three, or even four bowls from one blank, your return on investment increases significantly. This is especially beneficial for professional woodturners selling at craft shows or galleries.

Reduced Tool Wear

Hollowing large blanks traditionally puts significant stress on bowl gouges and hollowing tools. The Oneway coring system removes bulk material efficiently, reducing wear and tear on primary cutting tools.

Sustainability and Waste Reduction

Sustainable woodworking practices are trending across the industry. Coring supports environmentally responsible woodworking by reducing waste and maximizing resource usage.

Creative Opportunities

Nested bowl sets are highly desirable and visually appealing. Using the Oneway coring system opens creative possibilities that traditional hollowing cannot easily achieve.

Integrating Woodworking Abrasives with Coring Techniques

The true advantage comes when woodworking abrasives and the Oneway coring system are used together strategically.

After coring multiple bowls from a single blank, each piece must be properly refined. Because coring often leaves relatively consistent interior surfaces, sanding may be more efficient compared to aggressive hollowing methods.

Step 1: Initial Sanding

Begin with coarse woodworking abrasives to remove any coring tool marks and refine the shape.

Step 2: Progressive Refinement

Move through medium grits methodically. Maintain steady pressure and allow the abrasive to cut naturally without forcing it.

Step 3: Fine Surface Preparation

Finish with fine and ultra-fine grits to prepare the surface for oils or wax. Proper sanding enhances grain clarity, depth, and natural figure.

High-quality woodworking abrasives reduce heat buildup and resist clogging, ensuring consistent results across all nested bowls.

Efficiency and Workflow Optimization

Modern woodturners prioritize smart workflows. Combining woodworking abrasives with the Oneway coring system supports:

- Faster material removal

- Reduced sanding time

- Lower overall tool maintenance

- Increased output per blank

- Cleaner, more consistent finishes

This integrated approach allows hobbyists and professionals alike to work smarter rather than harder.

Why Tool Quality Matters

Not all abrasives or coring systems deliver the same results. Investing in reliable tools ensures consistent performance and long-term savings. High-quality woodworking abrasives last longer, cut cleaner, and reduce sanding fatigue. Likewise, a precision-engineered Oneway coring system provides stability, accuracy, and safety.

Vince’s Wood N’ Wonders supports woodturners by offering dependable solutions that align with modern woodworking demands. The right tools, combined with proper technique, elevate both craftsmanship and efficiency.

Conclusion: Precision, Performance, and Profit

Mastering woodworking abrasives ensures smooth, professional finishes that highlight the natural beauty of wood. Incorporating the Oneway coring system transforms how you approach material usage, enabling you to produce multiple high-quality pieces from a single blank.