Introduction: Why Engineering Quality Defines PIT Tag Performance

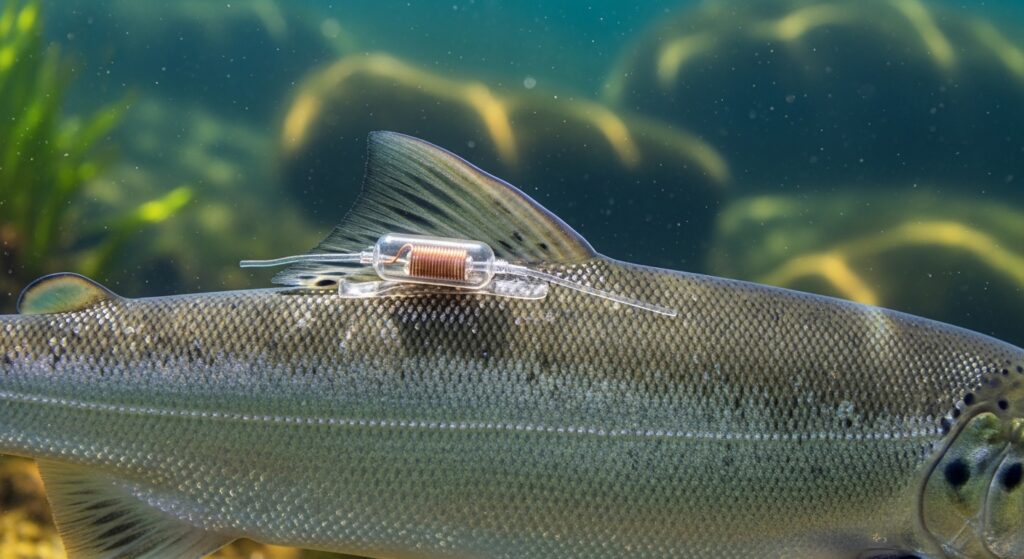

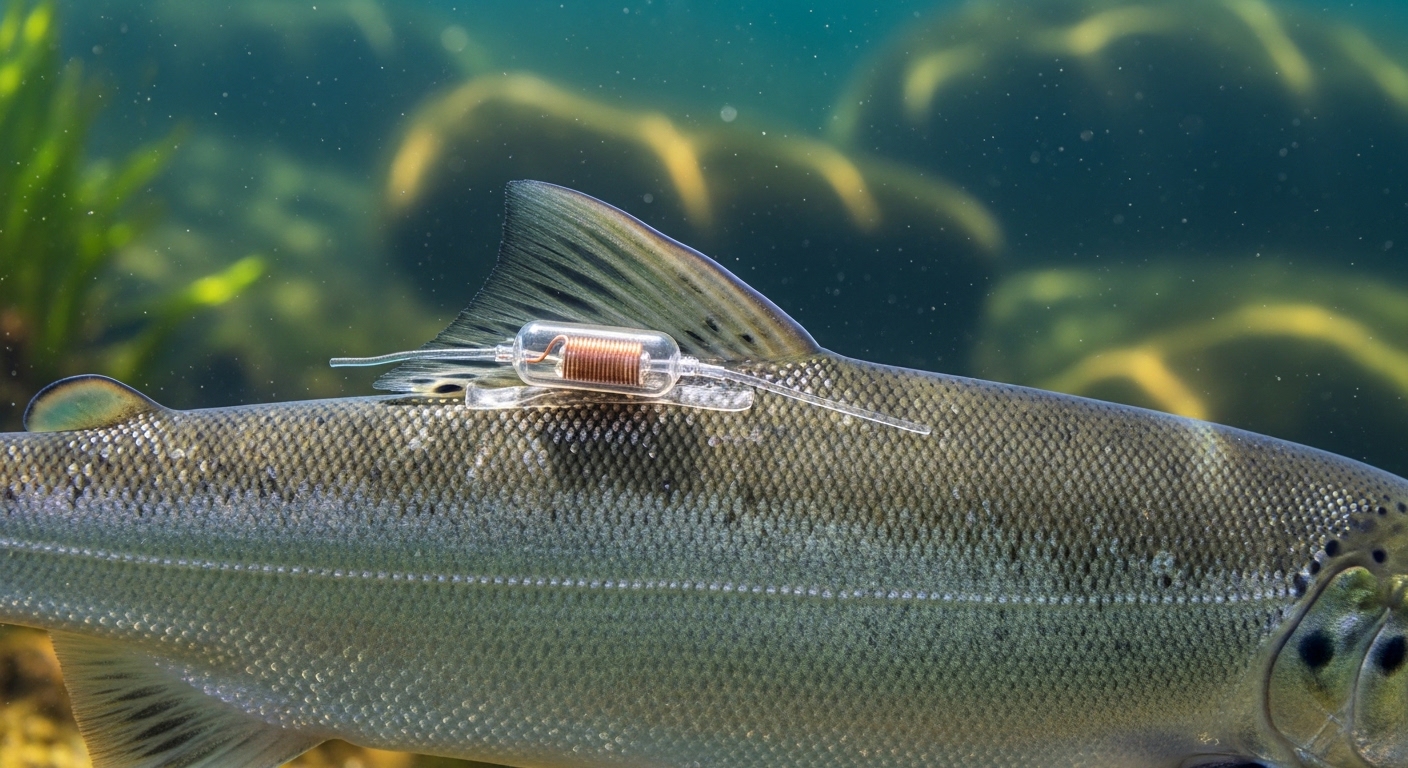

In aquatic research and fisheries management, the reliability of individual animal identification depends entirely on the quality of the tagging device itself. A tag that fails prematurely, loses signal strength, or degrades inside a host organism renders years of monitoring data incomplete and scientifically unreliable. This is why the engineering behind modern pit tags for aquatic monitoring has become a subject of serious scientific and commercial attention.

Pit tags — Passive Integrated Transponder tags — are deceptively simple in concept but remarkably sophisticated in execution. Their ability to function reliably inside living organisms for a decade or longer, transmit accurate identification signals through tissue and water, and resist the mechanical and chemical stresses of aquatic environments depends on a precise combination of materials science, antenna engineering, and manufacturing standards.

This article examines the key design factors that determine how well a pit tag performs over its operational lifetime — and why these factors matter deeply to researchers, conservation program managers, and procurement decision-makers.

The Foundation: Biocompatible Materials and Hermetic Sealing

The outermost layer of any pit tag is its first and most critical line of defense. The vast majority of high-quality pit tags are encased in borosilicate glass — a material chosen for its exceptional combination of properties:

- Biocompatibility: Borosilicate glass is inert within biological tissue, triggering minimal immune response in fish, amphibians, and other aquatic hosts.

- Chemical resistance: It resists degradation from body fluids, saline environments, and the acidic conditions found in some aquatic habitats.

- Mechanical strength: Despite its small size, glass-encased pit tags withstand considerable compressive and impact forces during implantation and normal animal activity.

The hermetic seal — the airtight closure of the glass capsule — is equally critical. Any micro-fracture or seal failure allows moisture ingress, which rapidly destroys the internal electronics. Premium manufacturers use laser-welded or flame-fused sealing techniques that guarantee integrity under ISO standards.

Some next-generation pit tags incorporate polymer coatings over the glass casing to enhance tissue adhesion and reduce migration within the host body — a meaningful improvement in studies requiring tag location stability for secondary data collection such as ultrasound imaging.

Internal Architecture: Microchip and Antenna Coil Design

Inside the glass capsule, two core components determine functional performance: the integrated circuit (microchip) and the copper or aluminum antenna coil.

Microchip Design

The microchip stores the tag’s unique identification code — typically a 15-digit ISO-compliant number under the 134.2 kHz frequency standard (ISO 11784/11785). Key microchip quality indicators include:

- Memory stability: High-quality chips use EEPROM (Electrically Erasable Programmable Read-Only Memory) architecture that retains data without power for 10+ years.

- Code uniqueness: ISO-compliant chips carry a manufacturer code plus a unique animal identification number, ensuring no two tags share the same code within a global namespace.

- Power harvesting efficiency: The chip must extract sufficient energy from the reader’s electromagnetic field to power transmission — even at low field strengths or suboptimal antenna alignment.

Antenna Coil Configuration

The copper coil wound around the ferrite core is the antenna that receives energy from the reader and transmits the identification signal back. Coil quality directly determines:

- Read range: More windings and tighter tolerances produce stronger inductive coupling, improving detection distance.

- Angular sensitivity: Well-designed coils maintain acceptable read rates across a range of tag orientations relative to the reader antenna — critical when tags rotate inside moving fish.

- Resonant frequency accuracy: Manufacturing tolerances must keep the coil’s resonant frequency precisely matched to the reader frequency. Deviation reduces signal strength and detection reliability.

Signal Integrity: Factors That Affect Detection Reliability

Even a perfectly manufactured pit tag can underperform if environmental and biological factors are not accounted for in system design. Understanding these variables is essential for researchers designing detection infrastructure.

Water Conductivity

Freshwater and saltwater environments differ dramatically in electrical conductivity. High-conductivity saltwater can attenuate the electromagnetic field generated by a reader antenna, reducing effective read range. Studies have shown that read range in seawater can be reduced by 30–50% compared to freshwater under equivalent antenna configurations. Researchers working in estuarine or marine environments must compensate with larger antenna arrays or higher-powered reader systems.

Tissue Depth and Tag Orientation

Signal transmission through biological tissue introduces additional attenuation. Tags implanted deeper within the body cavity — as is common in larger fish — experience greater signal loss than superficially implanted tags. Tag orientation also matters: a tag aligned perpendicular to the reader antenna produces significantly weaker coupling than one aligned parallel.

Research published in Transactions of the American Fisheries Society demonstrated that detection efficiency varied by up to 22% based solely on tag orientation within the host, underscoring the importance of both implantation technique and antenna design in maximizing detection probability.

Reader Field Uniformity

The electromagnetic field generated by a reader antenna is not perfectly uniform across its surface. Tags passing through the center of a loop antenna experience stronger fields than those near the edges. Fixed instream antenna arrays must be designed with sufficient overlap and redundancy to ensure consistent detection across the full cross-section of a monitored waterway.

Size Variants and Their Design Trade-Offs

Pit tags are manufactured in a range of sizes, each representing a different set of engineering trade-offs:

| Tag Size | Typical Dimensions | Common Application | Trade-Off |

| Full-size | 23 × 3.65 mm | Adult salmonids, large fish | Excellent read range, larger implant |

| Half-duplex mini | 12 × 2.1 mm | Juvenile fish, amphibians | Reduced read range |

| Nano | 8 × 1.4 mm | Small juveniles, invertebrates | Shortest read range, specialized readers needed |

The nano tag represents the frontier of pit tag miniaturization. Achieving reliable signal integrity at this scale requires advanced coil winding techniques and high-efficiency chip designs that push current manufacturing capabilities. VodaIQ offers a range of pit tag sizes engineered to meet these diverse research requirements with consistent quality standards.

Manufacturing Standards and Quality Assurance

Procurement decisions for large-scale tagging programs should always prioritize tags manufactured to recognized international standards:

- ISO 11784: Defines the code structure of the transponder.

- ISO 11785: Defines the technical concept of the transponder — how it communicates with readers.

- ICAR (International Committee for Animal Recording): Provides additional certification for tags used in livestock and wildlife applications.

Quality manufacturers subject pit tags to rigorous testing protocols including:

- Pressure testing: Simulating depth pressures experienced by deep-diving species.

- Temperature cycling: Verifying seal integrity across the thermal range of target environments.

- Vibration and impact testing: Ensuring survival through implantation procedures and active animal movement.

- Read rate verification: Batch testing to confirm signal output meets specification before shipment.

Researchers and procurement managers should request certificates of conformity and batch test reports from suppliers to verify compliance before deploying tags in long-term programs.

Longevity: What Real-World Data Tells Us

The longevity of pit tags in field conditions is well-documented. Long-term studies tracking tagged individuals over multiple years consistently report:

- Tag retention rates exceeding 95–99% across multi-year monitoring periods in salmonid studies.

- No measurable signal degradation in tags recovered from fish after 10+ years in field conditions.

- Negligible chronic tissue reaction around implanted tags in histological analyses of host tissue.

A landmark study monitoring Atlantic salmon (Salmo salar) over an eight-year period found zero cases of tag-related mortality attributable to the implant itself — reinforcing the case for pit tags as the gold standard for long-term individual identification in aquatic research.

Conclusion: Design Quality Is a Long-Term Investment

The durability, signal integrity, and design sophistication of modern pit tags are not incidental features — they are the product of decades of materials research, engineering refinement, and field validation. For researchers and program managers, selecting high-quality pit tags is not merely a procurement decision; it is a commitment to the integrity of every data point collected over the life of a monitoring program.

As tagging programs grow in scale and ambition, the engineering standards of pit tags will continue to evolve — with smaller sizes, improved signal performance, and enhanced biocompatibility opening new frontiers in aquatic science. Investing in proven, standards-compliant pit tags today ensures that your research data remains reliable, comparable, and scientifically defensible for decades to come.