Introduction

In modern healthcare, safety and accuracy are extremely important when delivering medicines to patients. Hospitals, clinics, and healthcare providers need reliable medical devices that ensure the correct dose of medicine is delivered without contamination or errors. This is where prefilled syringes play a very important role.

Prefilled syringes are ready-to-use syringes that already contain the correct amount of medication. They eliminate the need to manually fill syringes, which reduces the risk of contamination and dosage mistakes. These syringes are widely used for vaccines, insulin, biologics, and emergency medicines.

India has become one of the leading countries in pharmaceutical manufacturing. Prefilled syringe manufacturers in India produce high-quality syringes using advanced technology and strict safety standards. These manufacturers ensure safe, sterile, and accurate drug delivery for both domestic and international healthcare markets.

This article will explain everything about prefilled syringe manufacturers in India, their importance, features, manufacturing process, and how they ensure safe and accurate drug delivery.

What Are Prefilled Syringes?

Prefilled syringes are medical syringes that come preloaded with a specific dose of medication. They are designed for immediate use without the need for manual filling.

These syringes are commonly used for:

-

Vaccinations

-

Insulin injections

-

Blood thinner medications

-

Biologic therapies

-

Emergency treatments

Prefilled syringes help healthcare professionals deliver medicines safely and accurately.

Why Prefilled Syringes Are Important in Healthcare

Prefilled syringes have become essential in modern healthcare because they improve safety and efficiency.

They help in:

-

Reducing medication errors

-

Preventing contamination

-

Saving time for healthcare professionals

-

Ensuring accurate dosage

-

Improving patient safety

These benefits make prefilled syringes a preferred choice in hospitals and clinics.

Why Prefilled Syringe Manufacturers in India Are Important

India is known for its strong pharmaceutical and medical device manufacturing industry. Prefilled syringe manufacturers in India play a crucial role in supporting healthcare systems.

They ensure:

-

High-quality syringe production

-

Sterile and safe medical devices

-

Accurate drug delivery solutions

-

Affordable medical products

Indian manufacturers supply syringes to hospitals, pharmaceutical companies, and global healthcare markets.

Why Prefilled Syringes Are Better Than Traditional Syringe

Prefilled syringes offer many advantages over traditional syringes.

Improved Safety

Prefilled syringes are sealed and sterile, reducing contamination risk.

Accurate Dosage

They contain the exact amount of medicine, reducing dosage errors.

Easy to Use

Healthcare professionals can use them immediately without preparation.

Time Saving

They save time in emergency and routine treatments.

Reduced Medication Waste

They minimize medicine wastage.

These benefits improve healthcare efficiency and safety.

How Prefilled Syringe Manufacturers in India Ensure Safety

Safety is the top priority for manufacturers.

They ensure safety by following strict procedures.

Sterile Manufacturing Environment

Syringes are produced in clean rooms to prevent contamination.

Medical-Grade Materials

Manufacturers use high-quality materials safe for medical use.

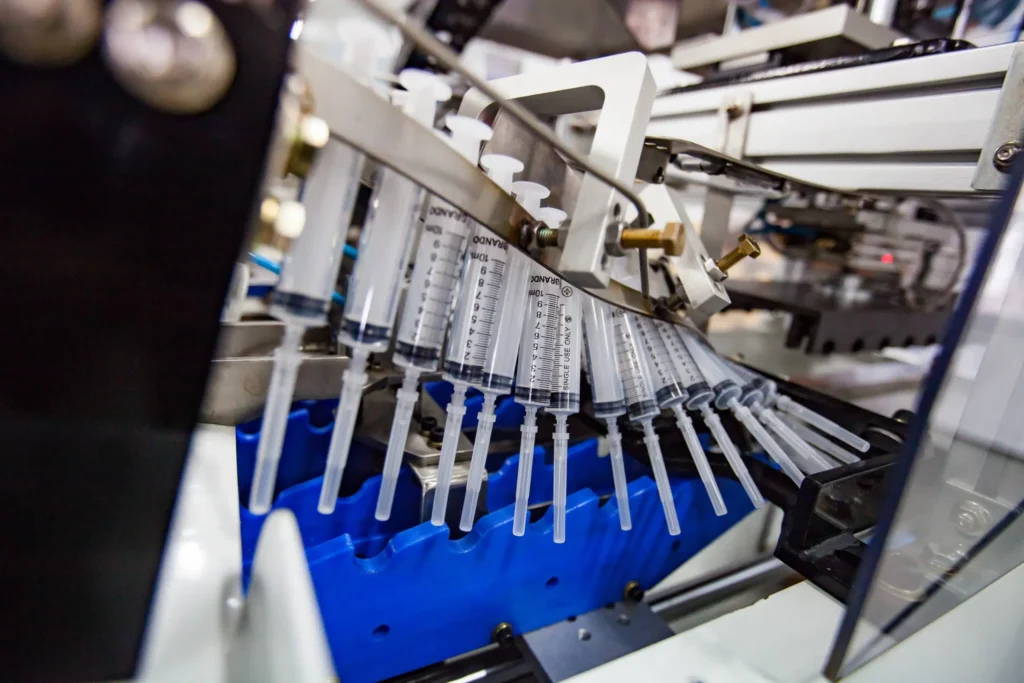

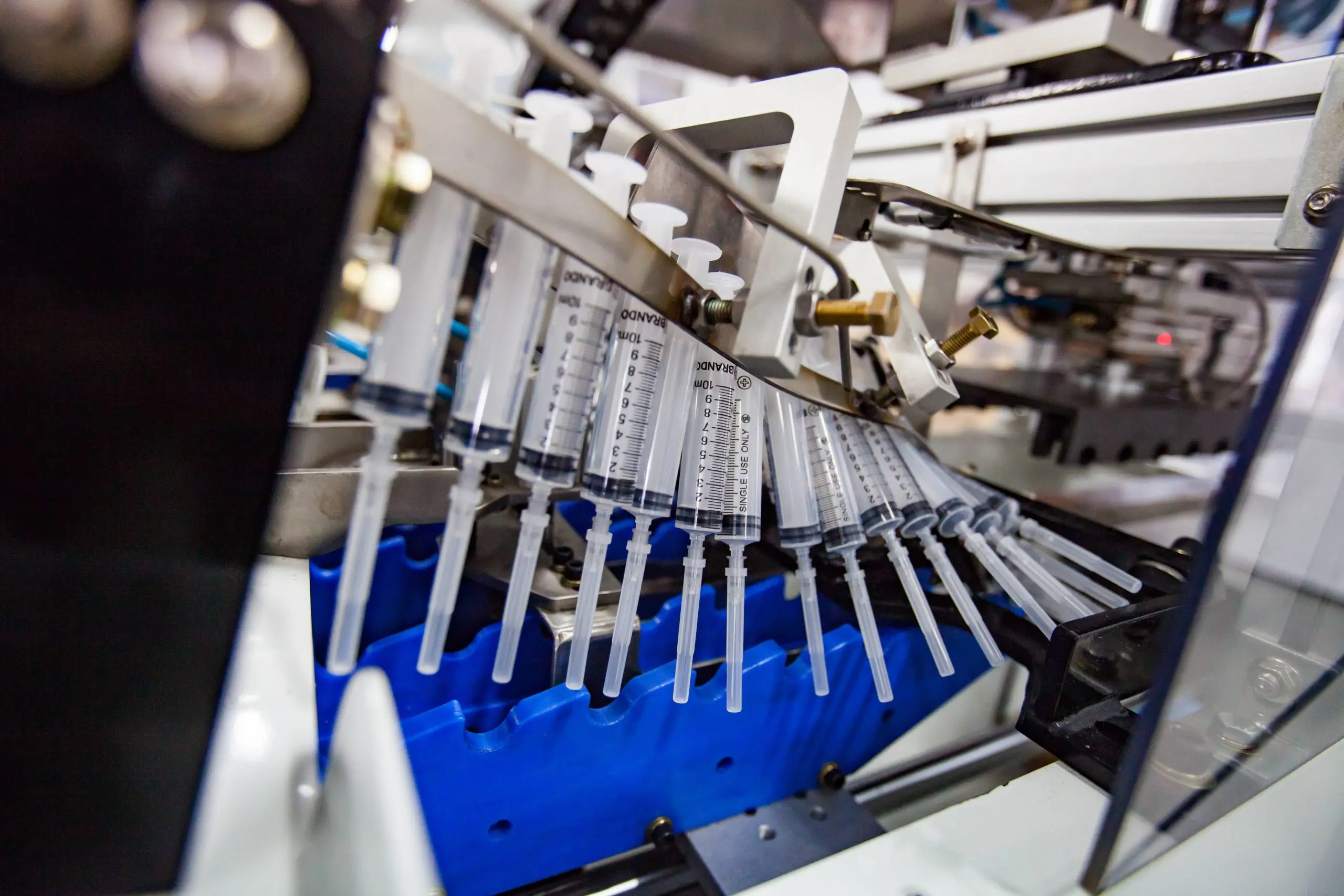

Advanced Manufacturing Technology

Automated machines ensure accurate filling and sealing.

Strict Quality Control

Each syringe is tested for safety and performance.

Compliance with International Standards

Manufacturers follow standards like ISO and GMP.

These measures ensure safe and reliable products.

Manufacturing Process of Prefilled Syringes

The manufacturing process involves several important steps.

Syringe Production

Syringes are made using medical-grade plastic or glass.

Cleaning and Sterilization

Syringes are sterilized to remove contaminants.

Filling with Medication

Machines fill syringes with precise doses.

Sealing

Syringes are sealed to maintain sterility.

Quality Testing

Each syringe is tested for accuracy and safety.

Packaging

Syringes are packaged in sterile conditions.

This process ensures high-quality products.

Types of Prefilled Syringes Manufactured in India

Indian manufacturers produce different types of prefilled syringes.

Glass Prefilled Syringes

These offer excellent chemical stability.

Plastic Prefilled Syringes

These are lightweight and durable.

Disposable Prefilled Syringes

These are used once and safely discarded.

Safety Prefilled Syringes

These include safety features to prevent needle injuries.

These options meet various medical needs.

Applications of Prefilled Syringes

Prefilled syringes are used in many medical applications.

Vaccination

Used for vaccine delivery.

Diabetes Treatment

Used for insulin injections.

Emergency Care

Used for emergency drug administration.

Chronic Disease Treatment

Used for long-term treatments.

Biologic Drug Delivery

Used for advanced therapies.

These applications ensure effective patient treatment.

Why Choose Prefilled Syringe Manufacturers in India

India is a trusted hub for prefilled syringe manufacturing.

High Quality Standards

Manufacturers follow global quality standards.

Affordable Pricing

Indian products are cost-effective.

Advanced Technology

Manufacturers use modern machines.

Skilled Workforce

India has experienced professionals.

Global Export Capability

Indian manufacturers supply worldwide.

These factors make India a reliable choice.

How Prefilled Syringes Ensure Accurate Drug Delivery

Prefilled syringes ensure accurate drug delivery through:

-

Precise filling technology

-

Exact dosage control

-

Secure sealing

-

Sterile packaging

This reduces errors and improves patient safety.

Future of Prefilled Syringe Manufacturing in India

The future is very promising.

Growth factors include:

-

Increasing healthcare demand

-

Growth in pharmaceutical industry

-

Rising vaccination programs

-

Technological advancements

India is becoming a global leader in medical device manufacturing.

How to Choose the Best Prefilled Syringe Manufacturer in India

Consider these factors:

Quality Certifications

Check ISO and GMP certification.

Manufacturing Experience

Choose experienced manufacturers.

Technology Used

Advanced machines ensure better quality.

Product Safety

Ensure strict safety standards.

Customer Support

Reliable support is important.

This ensures safe and reliable products.

Conclusion

Prefilled syringe manufacturers in India are an important innovation in healthcare. They ensure safe, sterile, and accurate drug delivery. Prefilled syringe manufacturers in India play a vital role in producing high-quality syringes that meet global standards.

They use advanced technology, sterile environments, and strict quality control to ensure safety and accuracy. Prefilled syringes reduce errors, save time, and improve patient safety.

India is becoming a leading global supplier of prefilled syringes due to its quality manufacturing, affordability, and advanced technology.

Choosing trusted prefilled syringe manufacturers in India ensures safe and effective healthcare solutions.

FAQ Section

What are prefilled syringes?

Prefilled syringes are syringes already filled with medication and ready for use.

Why are prefilled syringes safer?

They reduce contamination and ensure accurate dosage.

Are prefilled syringes manufactured in India high quality?

Yes, Indian manufacturers follow international safety standards.

Where are prefilled syringes used?

They are used in vaccines, insulin, and other medical treatments.

Why choose Indian manufacturers?

They offer high quality, affordable pricing, and global standards.