In industrial conveyor systems, belt dimensions directly affect performance, durability, and load-handling efficiency. The width and thickness of an Eagle Belt 0.50 determine how well it transports materials, withstands operational stress, and integrates with conveyor components. Understanding these factors helps engineers and maintenance teams optimize material flow while reducing downtime. Properly selected belts also enhance workplace safety, reduce energy consumption, and improve the lifespan of other conveyor components.

Importance of Belt Width

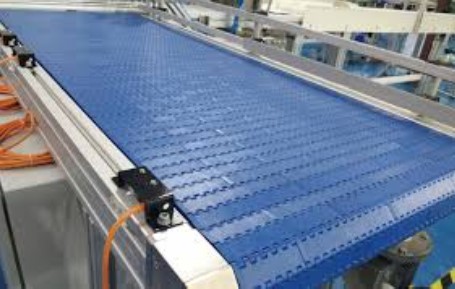

Belt width influences load stability and distribution. Wider belts provide more surface area, helping heavy or uneven materials stay centered on the conveyor. Proper width selection ensures smooth operation, reduces edge wear, and prevents misalignment that could lead to costly maintenance or product damage. In addition, wider belts can accommodate larger or multiple items per load, improving productivity for high-volume packaging operations. Narrow belts may save space but require more precise alignment and monitoring, highlighting the importance of matching belt width to the type of material transported.

Impact of Belt Thickness

The thickness of a belt contributes to its strength and flexibility. Thicker belts can support heavier loads and resist stretching, while thinner belts offer greater flexibility for tight curves or smaller pulleys. Matching the thickness to operational needs maintains reliable performance and prolongs belt life. Thicker belts also help absorb shock from sudden starts and stops in automated lines, reducing wear on both the belt and conveyor structure. This consideration is particularly important in facilities where heavy or abrasive materials are transported regularly.

Load Capacity and Durability

Optimal belt dimensions enhance both load capacity and durability. A belt that is too narrow or thin can sag or slip under weight, causing wear on rollers and tensioning systems. Correct sizing ensures consistent tracking, minimizes maintenance, and improves overall reliability in demanding production environments. Additionally, belts with the proper width and thickness reduce the likelihood of misalignment or slippage, which can damage products or create safety hazards. Facilities that invest in correctly dimensioned belts experience fewer operational interruptions and lower overall repair costs.

Integration with Conveyor Systems

The Eagle Belt 0.50 must fit seamlessly with other packaging equipment parts. Compatibility with pulleys, guides, and tensioning devices is critical to prevent mechanical strain or misalignment. Proper dimensional selection ensures smooth integration and operational efficiency across the entire packaging line. When belts are selected without considering compatibility, conveyors may experience uneven tension, increased motor wear, or frequent belt replacements. Integrating the belt effectively with existing equipment reduces maintenance needs and allows the system to operate at full capacity with minimal disruption.

Material Handling Efficiency

Correct width and thickness also improve material handling. Stable, well-supported loads reduce spillage, tipping, or product damage. The belt’s design ensures consistent movement, which is essential for maintaining high throughput and meeting production targets in industrial facilities. Properly designed belts also help prevent jams and bottlenecks, which can slow operations and affect overall productivity. By improving load stability and minimizing operational interruptions, conveyors equipped with appropriately sized belts maintain reliable and efficient performance across multiple shifts.

Maintenance and Safety Considerations

Belt dimensions affect maintenance schedules and workplace safety. Properly sized belts experience less uneven wear and require fewer adjustments. This reduces operational interruptions and lowers the risk of accidents caused by slipping or shifting materials. A well-chosen belt safeguards both equipment and employees. Regular inspections of width, thickness, and tension further ensure safety while extending the operational life of the belt and associated conveyor components.

Long-Term Benefits

Investing in a belt with appropriate width and thickness provides long-term operational advantages. Integration with other packaging equipment parts ensures smooth workflow, reduced downtime, and lower maintenance costs. Facilities benefit from enhanced efficiency, reliable material transport, and extended service life for both belts and machinery. Selecting the correct dimensions also reduces energy usage by minimizing belt strain, allowing motors and drives to operate optimally. Over time, these improvements contribute to cost savings and higher production reliability.

Conclusion

Width and thickness are crucial factors in conveyor performance. An Eagle Belt 0.50 with correctly chosen dimensions provides stable load handling, seamless integration, and long-lasting durability. Aligning belt specifications with operational requirements ensures safe, efficient, and cost-effective material handling in industrial settings. Facilities that prioritize belt sizing benefit from smoother operations, fewer maintenance interruptions, and improved productivity while maintaining workplace safety standards.